2200mm ABA Three Layers Coextrusion Film Blowing Machine

A: Description 1. The machine take the HDPE or LDPE as raw material, through heating, extrusion, blowing, stretch, winde;

Basic Info

| Model NO. | F3B-ABA |

| After-sales Service | Technical Support Online |

| Warranty | One Year |

| Type | Multi-Layer Co-extrusion Film Blowing Machine |

| Raw Material | PE |

| Maximum Folding Width of Film | 2200mm |

| Screw Diameter | 60mm |

| Automation | Automatic |

| Computerized | Computerized |

| Machine Weight | 4T |

| Certification | CE, ISO9001:2008 |

| Film Type | Three Layers Coextrusion |

| Material | PE/CaCO3/PE |

| Screw Quantity | 2 Set |

| Die Head | ABA Die Head |

| Heating Ring | Cast Aluminum |

| Winder Type | Friction Single Station |

| Auto Winder | Optional |

| Rotary Die Head | Optional |

| Transport Package | Stretch Film or Wooden Case |

| Specification | CE, ISO9001 |

| Trademark | HOIN |

| Origin | Ruian, Zhejiang, China |

| HS Code | 8477301000 |

| Production Capacity | 30 Set/Month |

Product Description

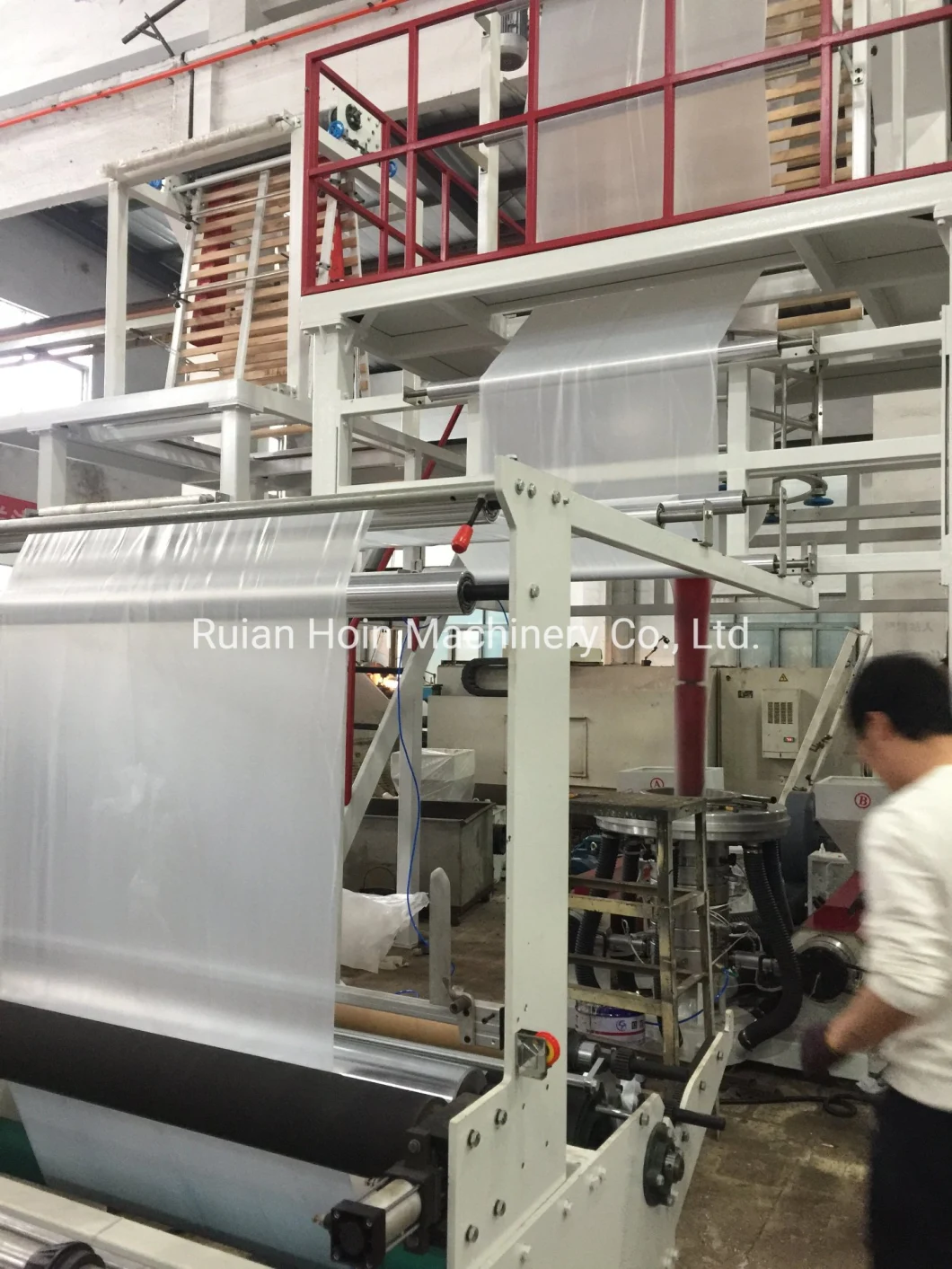

A: Description1. The machine take the HDPE or LDPE as raw material, through heating, extrusion, blowing, stretch, winder and final be roll thin film. 2. The finished plastic thin film is widely used for supermarket bag, garbage bag, various plastic package bag, farmland film. Cote film and compound thin film. 3. Put more recycling material to save the cost.

B: Technology Parameter

| Model | FB-ABA-700 | FB-ABA-900 | FB-ABA-1300 | ||||

| Applicable Materials | LDPE LLDPE HDPE EVA | ||||||

| Max. Width of Film | 600 | 800 | 1200 | ||||

| Thickness of Film | 0.01-0.10mm | ||||||

| Max. Extrusion Output | HD: 60kg/h LD: 70kgs/h | HD: 75kg/h LD: 85kgs/h | HD: 90kg/h LD: 100kgs/h | ||||

| Screw Diameter | Φ45*2 | Φ50*2 | Φ55*2 | ||||

| Screw L/D Ratio | 30: 1 | ||||||

| Rotate Speed of Screw | 10-80r/min | ||||||

| Screw&Barrel Material | SAC-645/38CroMoALA | ||||||

| Main Motor Power | 11kw*2 | 15kw*2 | 18.5kw*2 | ||||

| Heating Ring | Cast Aluminum | ||||||

| Temperature Control | 3Zones*2 | 3Zones*2 | 3Zones*2 | ||||

| Screen Changer | Manual Type | ||||||

| Diameter of Die Orifice | HD: Φ550 LD: Φ160 | HD: Φ80 LD: Φ180 | HD: Φ130 LD: Φ250 | ||||

| Air Ringc | Double Air Vent Air Ring | ||||||

| Blower Motor | 3kw | 4kw | 5.5kw | ||||

| Take up Motor | 1.5kw | 2.2kw | 3kw | ||||

| Winder | Friction Single Station | ||||||

| Air Shaft Roller | 2 Pieces | 2 Pieces | 2 Pieces | ||||

| Total Power | 40 | 45 | 56 | ||||

| Weight of Machine | 3.5T | 4T | 5T | ||||

| Overall Dimension | 5X3.5X5 | 5.5X3.7X5 | 6.5X4.1X5.2 | ||||

1. Extruder Unit

Die Head Material: Cr40 Mould Steel

Die Head Heating: 2 Zones

Rotary Die Head: Optional

Screw and Barrel Material: 38CrMoALA

Screw and Barrel Heating: 3Zones*3Sets

Heating Ring Material: Cast Aluminum

Screen Changer: Manual Type

Gear Box: Hard Tooth Surface Gear Box

2. Take Up Section

'A' Shape Film Forming Plate: Wooden Bar Type

Film Bubble Setting Ring: Wooden Bar Type

Take Up Motor: Three-Phase Asynchronous Motor with Worm Gear Reducer

Take Up Rollers Grasp: Air Cylinder

3. Winder Unit

Second Take Up Unit: Air Cylinder

Rewinding Station: Double Stations

Rewinding Motor: Torque Motor

Pinch Roller: Air Shaft Roller

D. After service of HOIN

1. How long will your engineer reach to our factory?

Within one week after machine arrival at your factory.

2. How many days will you finish installing?

We will finish installation and training within 15days.

3. What should we charge for your engineer?

You should charge for the cost of our engineer's visa, air tickets, hotel, food, and also their salary 100USD per day per person.

4. How long of your machine's warranty period?

All our machines have one year guarantee after finishing installation under normal operation.

5. How could we do after one year warranty period?

We also can offer you our best after service, of course you will afford our technician's cost.

6. Can you find us any engineer in our location?

Of course, we will check and inform you as soon as possible.

Any query pls feel to contact with us! Ms. WendyPan

E. HOIN WorkshopF. Loading & Shipping

You may also like

Send inquiry

Send now